Palm oil, derived from the oil palm tree’s fruit, is an environmentally friendly product that is prevalent in both daily life and industrial production. However, during the production process, palm oil may contain impurities that require refining to obtain the final refined palm oil product.

Activated carbon plays a crucial role in the refining process, particularly in the decolorization stage. This article will focus on the application and advantages of activated carbon in palm oil production.

The Significance of Palm Oil

Palm oil holds a significant position in the global oil and fat market, accounting for over 30% of the total world fat production. As a vegetable oil, palm oil can replace other fats such as soybean oil, peanut oil, sunflower oil, and coconut oil.

Rich in nutrients, palm oil is widely used in the food and beverage industry and oleochemical industry. In China, palm oil is known as the “industrial MSG” for its industrial applications.

The industrial uses of palm oil fall into two main categories: direct products obtained from palm oil, including soaps, polypropylene esters, and epoxy palm oil products, and oleochemical products such as glycerol, fatty acids, and nitrogen-containing compounds.

Palm Oil Production Process

After reading about the crucial role of palm oil in the global market, let’s delve into the detailed production process of this widely used edible oil.

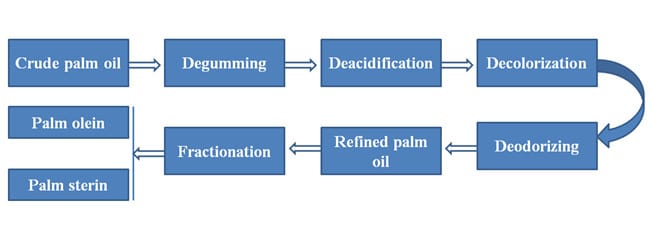

The production of palm oil involves two main processes: crude processing, where the oil palm fruit undergoes simple processing to obtain crude palm oil with numerous impurities, and refined processing, which includes degumming, deacidification, decolorization, and deodorization.

Among these processes, decolorization is the most crucial step in palm oil refining. The commonly used agents for decolorization are activated carbon and activated bleaching earth.

Do you plan to purchase activated carbon?

The Significance of Activated Carbon in Decolorization

Activated carbon has an oil absorption rate of 100% to 150%, but its filtration speed is slow.

Therefore, it is commonly used in combination with activated bleaching earth. This combination not only enhances decolorization and detoxification but also reduces the cost of decolorization and oil loss.

Activated carbon, with its excellent porous adsorption medium, plays a vital role in the palm oil refining process. Its developed porous structure, with pore sizes ranging from 1.5nm to 5um, makes it highly effective in removing pigments and impurities from palm oil.

In palm oil processing, activated carbon effectively removes toxins such as benzopyrene and aflatoxin. Due to its porous and hydrophobic nature, activated carbon can adsorb large molecular substances, demonstrating excellent adsorption for green and blue pigments.

Compared to activated bleaching earth, activated carbon results in lower red values and better decolorization without any undesirable odors.

Why Purchase Activated Carbon from Us?

As one of China’s leading activated carbon manufacturers, suppliers, and exporters, we have been in the activated carbon industry since 2010. Specifically designed for palm oil decolorization, we offer wood powder activated carbon.

Below are some product specifications for your reference

| Specification | Size (mesh) | Molasses Number | Caramel Decoloration (mg/g) | MB | PH | Iron (Fe+) (%) | Ash (%) | Iodine Value (mg/g) |

|---|---|---|---|---|---|---|---|---|

| Powdered Activated Carbon | 100, 200, 300 | 150-180 | 100-130 | 150-280 | 3-11 | 0.02-0.05 | ≤5 | 300-1050 |

Do you plan to purchase activated carbon?

Final Thoughts

The above provides a brief overview of the application of activated carbon in palm oil decolorization, and there is much more to explore regarding the knowledge related to palm oil decolorization.

If you want more information or have any inquiries, please feel free to contact us. At Zhulin, we have extensive production experience and a professional team, offering high-quality and cost-effective activated carbon solutions.

For further details, please reach out to us.