Phosphoric acid is an important chemical raw material, widely used in fertilizers, food, detergents, metallurgy and other fields. However, phosphoric acid often contains a variety of impurities, such as metal ions, silicates, fluorides, etc. These impurities will affect the quality and performance of phosphoric acid, so it needs to be purified.

This blog mainly describes the production and the purification method of phosphoric acid, and the role of activated carbon.

Phosphoric acid production method

At present, there are two main methods for the production of phosphoric acid: thermal method and wet method.

Thermal phosphoric acid production

Thermal phosphoric acid production is to produce yellow phosphorus by electric furnace method, and then obtain purer industrial phosphoric acid through oxidation and absorption. The phosphoric acid produced by this method has high purity, but the production cost is also relatively high. It is mainly used in fields with high requirements for phosphoric acid purity.

Wet phosphoric acid production

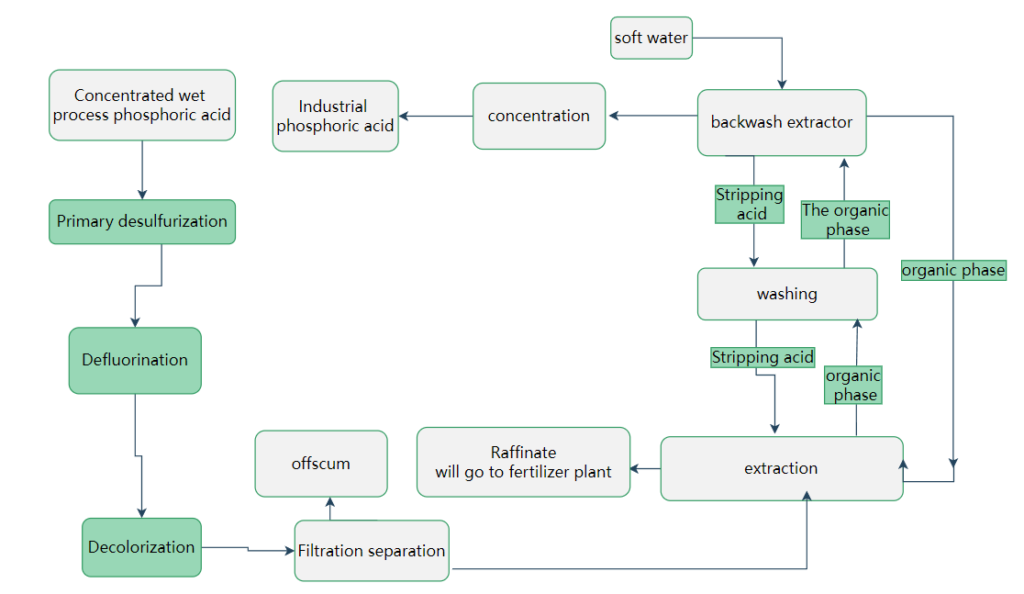

Wet phosphoric acid production is to decompose phosphate ore with strong acids such as sulfuric acid or hydrochloric acid, and obtain phosphoric acid containing various impurities after liquid-solid separation. Wet phosphoric acid has a low production cost and is mainly used to make phosphate fertilizers. If you want to produce high-quality phosphate products, you need to purify it further.

Phosphoric acid purification method

The main methods for phosphoric acid purification are chemical purification method and physical purification method.

Chemical purification method

The chemical precipitation method is to add a certain amount of chemical precipitant to wet phosphoric acid, and through a series of single reactions or synergistic reactions, the impurity ions are made to form precipitates that are insoluble in phosphoric acid. At present, the main research directions are defluorination, desulfurization and removal of metal ions.

Physical purification method

The physical adsorption method uses adsorbents with high surface free energy such as activated carbon to automatically adsorb organic impurities that reduce their surface energy, and then purify wet phosphoric acid through liquid-solid phase separation. The most commonly used adsorbents are activated carbon, activated silicon adsorbents and diatomaceous earth.

How does activated carbon purify phosphoric acid

Activated carbon plays a vital role in phosphoric acid purification, especially in the production of wet phosphoric acid. Activated carbon has a highly developed pore structure and a huge specific surface area, which makes it an excellent adsorbent. The following is a detailed process of activated carbon purification of phosphoric acid:

Adsorption of impurities:

Wet phosphoric acid contains various organic and inorganic impurities. Activated carbon adsorbs these impurities through the pore structure on its surface. The high surface free energy of the activated carbon surface enables it to adsorb organic impurities that reduce surface energy, such as oil and pigment.

Removal of metal ions:

Wet-process phosphoric acid often contains metal ions such as zinc, cadmium, copper and lead. The research have shown that impregnated carbon can effectively remove these metal ions. This is achieved through an ion diffusion process, where the metal ions are adsorbed by the pores of the activated carbon and combined with triphenylphosphine sulfide to form a stable complex, which is then removed.

Conclusion

There are many types of impurities in wet-process phosphoric acid, and different application fields have different quality requirements for phosphoric acid. Different purification methods can be selected according to actual needs. If a single purification technology does not meet the requirements for food grade or pharmaceutical grade phosphoric acid purity, a combination of two or more purification technologies can be used to give full play to the advantages of various purification technologies.

The technology for purifying phosphoric acid is constantly developing. In order to obtain high-quality phosphoric acid products, it is crucial to choose a suitable purification method. For an efficient adsorbent solution, Zhulin Carbon will provide you with the best products and services to help you improve product quality and achieve higher production efficiency.