Granular activated carbon is a widely used activated carbon. With its unique pore structure and high specific surface area, it plays an important role in many fields such as water treatment, air purification, and chemical production. Have you ever wondered how does it works? This article will give you an in-depth understanding of the adsorption mechanism of granulated activated carbon.

Granular Activated Carbon Overview

Simply put, activated carbon granules is made from various organic raw materials such as wood, coal, fruit shells, etc. after high temperature carbonization and activation treatment. The surface of granular activated carbon gac has a large number of micropores and pore structures, and these micropores can adsorb and immobilize a variety of harmful substances, such as organic compounds, heavy metals, odors, etc., so that they can be removed from liquids or gases, and purification purposes can be achieved.

Granular Activated Carbon Working Principle:

The working principle of activated carbon granules involves complex physical and chemical processes, and its adsorption mechanism is mainly divided into two categories: physical adsorption and chemical adsorption. These two adsorption mechanisms interact between the microstructure of activated carbon and the characteristics of pollutant molecules, thus realizing the efficient removal of pollutants by granulated activated carbon. Next, we will discuss the adsorption mechanism of granular activated carbon in depth.

Physical Adsorption

Physical adsorption refers to the adsorption force between the adsorbent and the adsorbate which is mainly due to intermolecular van der Waals forces. Physical adsorption is characterized by reversibility, non-selectivity and low heat of adsorption. The pore structure of granular activated carbon determines that it has a large specific surface area and pore volume, which provides abundant adsorption sites and gives it a high physical adsorption capacity.

Main Factors Affecting Adsorption Properties:

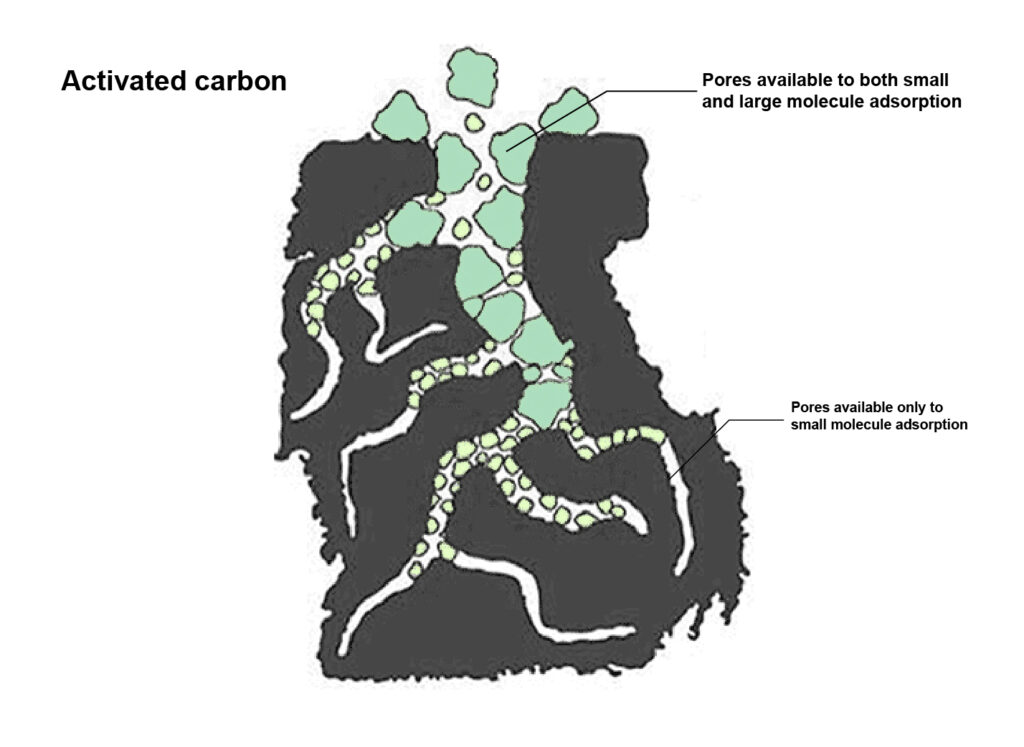

- Pore Structure and Surface Area: The pore structure of activated carbon is crucial to its adsorption capacity. Activated carbons with more, larger, and wider micropores, mesopores, and macropore structures generally have higher surface areas and therefore stronger adsorption capabilities.

- Temperature: Elevated temperatures usually diminish physical adsorption because the adsorption process is exothermic, and elevated temperatures encourage adsorbed molecules to detach from the surface of the activated carbon.

- Substance concentration: In general, higher concentrations of pollutants result in higher adsorption rates and adsorption volumes. However, within a certain concentration range, adsorption may reach saturation, at which point increasing the concentration of the pollutant will not increase the amount of adsorption.

- PH: The pH of the solution affects the chemical properties of the contaminants in the solution, which in turn affects their interaction with the activated carbon surface. Different contaminants may exhibit different adsorption behaviors at different pH conditions.

An in-depth understanding of the effects of these factors on the adsorption performance of activated carbon can help optimize the design and application of activated carbon and improve its adsorption efficiency and performance.

Chemical Adsorption

Chemisorption is the adsorption force between the adsorbent and the adsorbate mainly due to the formation of chemical bonds. Chemisorption has strong selectivity and high heat of adsorption, but the adsorption rate is slow. The surface of granular activated carbon is rich in functional groups, such as hydroxyl, carboxyl and amine groups, which can react chemically with the adsorbent to realize chemical adsorption.

By these two adsorption methods working together, activated carbon granules becomes an efficient purification material.

Conclusion

Through the introduction of this article, we have an in-depth understanding of the adsorption mechanism of granular activated carbon and its wide range of applications in various fields. If you need a deeper understanding or have any questions, please don’t hesitate to contact us. Our team has extensive experience and expertise and will provide you with the highest quality services and solutions. We look forward to further communication with you to discuss the application of granular activated carbon in the fields you are concerned about.