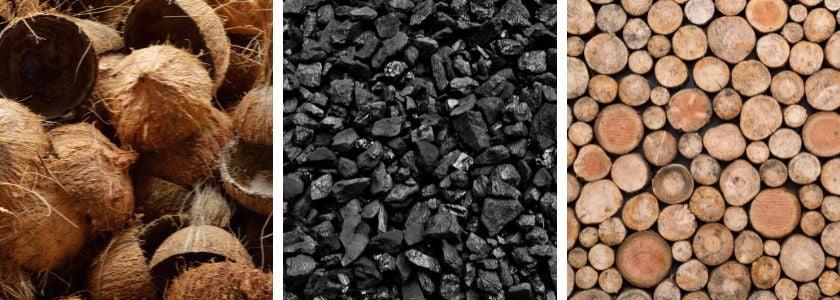

Utilizing different raw materials such as coconut shell, wood, and coal, activated carbon is produced through high-temperature carbonization, activation, and refinement, resulting in different types of activated carbon.

In this article, you can learn about the differences among these three types of activated carbon in terms of production processes, pore distribution, applications, physical characteristics, and usage costs.

Wood Activated Carbon

It is produced from selected wood materials using both physical and chemical methods to create activated carbon with advantages such as high porosity, large molecular adsorption capacity, high permeability, and purity.

Coal-Based Activated Carbon

Coal-based activated carbon is made from coal mines (such as bituminous coal, anthracite, and lignite) using chemical methods like steam activation. It features a developed pore structure, excellent adsorption performance, and high mechanical strength.

Coconut Shell Activated Carbon

Primarily made from coconut shells, coconut shell activated carbon is prepared through steam and phosphoric acid activation. It possesses numerous micropores and a small number of larger pores, enabling better adsorption of volatile organic compounds.

The Major Differences

Although all three types of activated carbon are produced through physical or chemical methods, differences arise from their varied raw materials.This is reflected in the following aspects

Production Manufacturing

- Coal-based activated carbon is mainly prepared through physical carbonization and chemical activation.

- Wood activated carbon is primarily produced through chemical methods such as steam and phosphoric acid activation.

- Coconut shell activated carbon is mainly produced through chemical methods, such as steam activation.

Pore Distribution

- The pore distribution of coal-based activated carbon is diverse, with abundant micropores.

Activated carbon made from bituminous coal has a vast surface area of micropores, with micropore volumes and carbon contents ranging from 70% to 90%, making it an ideal coal type.

Activated carbon produced from lignite has larger diameter pores. - Wood activated carbon contains relatively abundant mesopores and micropores, offering advantages such as high porosity, large molecular adsorption capacity, high permeability, and purity.

- Compared to other types of activated carbon, coconut shell activated carbon has a larger surface area and higher micropore density. With a high pore volume, its micropores are 50% more than those of coal-based activated carbon.

Applications

- Coal-based activated carbon has strong adsorption capabilities for various organic substances in water, free chlorine, and harmful gases in the air.

It serves as an excellent adsorbent for deep purification of urban drinking water and is used in wastewater treatment, industrial air purification, water purifiers, purification in the food and beverage industry, as well as medical and pharmaceutical applications. - Wood activated carbon, with high adsorption rates and fast filtration speeds, is commonly used in food decolorization, water purification, air purification, solvent recovery, and deodorization in the food and beverage industry.

- Due to its high hardness, low ash content, and high purity, coconut shell activated carbon is more suitable for drinking water treatment and reverse osmosis water applications.

Physical Characteristics

- Coal-based activated carbon is available in granular, pelleted, and powder forms.

- Coconut shell activated carbon is mainly in granular form.

- Wood-based carbon is mainly in powder form.

Raw Material Sources

- The raw material for coal-based activated carbon is coal mines, which are limited and non-renewable, with high impurity content. Both bituminous coal and anthracite can be used as raw materials.

Bituminous coal has the advantage of good chemical reactivity and low ash content, while anthracite has low ash, low sulfur, and high carbon content. - Coconut shell activated carbon is primarily made from coconut shells, a byproduct of coconut trees.

Coconut trees are perennial, making coconut shells a renewable resource with higher purity compared to other materials. - The raw material for wood activated carbon is mainly wood.

Additionally, carbonized wood or charcoal made from plants is a renewable and truly clean form of carbon.

Usage Costs

In general:

The raw material cost of coconut shell activated carbon is the highest, followed by coal mines, and lastly wood.

However, specific usage costs depend on the intended application and corresponding product requirements. If you would like more information in this regard, feel free to contact us.

Coconut Shell Activated Carbon | Coal Activated Carbon | Wood Activated Carbon | |

Production Manufacturing | Physical Carbonization and Chemical Activation | Chemical Methods | Chemical Methods |

Pore Distribution | More Micropores | More Mesopores and Less Micropores | More Mesopores and Macropores |

Application | Dechlorination Purification of Drinking Water | Powder Form Decolorization Treatment | Odor Removal |

Physical Characteristics | Mainly Granular | Mainly Powdered | Granular, Pelleted, Powder |

Raw Material Sources | Coconut Shell | Wood | Coal MInes |

Usage Costs | High | Low | Intermediate |

The table above provides a summary of the main differences among coconut shell, wood, and coal-based activated carbons.

Conclusion

Coconut shell activated carbon, wood activated carbon, and coal-based activated carbon each have unique characteristics and applications. When choosing, it is essential to balance specific requirements, environmental considerations, and sustainability factors.

Generally, coal-based activated carbon is most suitable for removing odors, coconut shell activated carbon is suitable for dechlorination, and wood activated carbon is most suitable for powder-based decolorization.

If you wish to learn more about activated carbon, please click the button below, and we will provide you with the best solutions. When selecting activated carbon products, it is crucial to consider various factors to ensure optimal performance and sustainability.